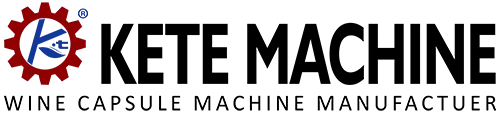

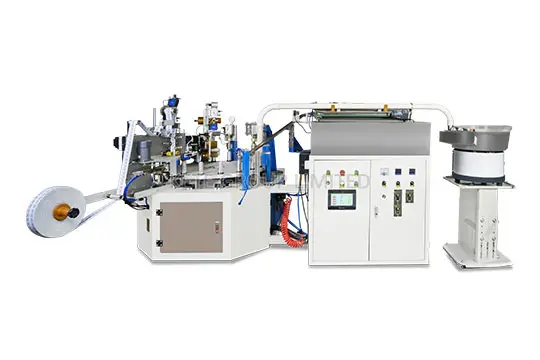

Customized Heat Shrink Sleeve Seaming Machine

Seaming for PVC / PET Heat Shrink Sleeves

KTGP-S

300

m/min

Speed

600

mm

Diameter

Yes

With Mold

Customized Heat Shrink Sleeve Seaming Machine

Seaming for PVC / PET Heat Shrink Sleeves

KTGP-S Series Heat Shrink Sleeve Seaming Machine

This High Speed Heat Shrink Sleeve Seaming Machine Is Used to Seaming PVC or PET Shrink Film Material to Sleeve Type. It Is Widely Used for Bottle Labels, Wine Bottle Capsules, and Security Sealing Capsules.

Features

- Unwind Tension Magnetic Power Brake

- Unwind use EPC Control System

- In-feed By Inverter Control

- Rewind By Inverter Control

- Use PLC Touch Screen

- Optional: Vertical Perforation

- Optional: Vertical Tear Off Tape

Price Start From: US$ 20,000.00

Great! I’d like to share this machine:

Let Our Experience Work For You

Machine Specifications

Model

KTGP-S250

Model

KTGP-S300

Raw Materials

Shrink PVC Film / PET-G Film

Raw Materials

150Capsules/min

Finished Sleeve Width

35-250mm (1.4”-9.8”)

Finished Sleeve Width

60-300mm (2.4”-11.8”)

Max. Unwind Diameter

Φ600mm (23.6”)

Max. Unwind Width

Φ600mm (23.6”)

Max. Unwind Width

600mm (23.6”)

Max. Unwind Width

650mm (25.6”)

PVC /PET-G Film Thickness

20-80mic (0.79”-3.1”)

PVC /PET-G Film Thickness

20-80mic (0.79”-3.1”)

Max. Mechanical Speed

300m/min

Max. Mechanical Speed

300m/min

Machine Power

3.5kw

Machine Power

4.5kw

Machine Weight

About 1000kg

Machine Weight

About 1200kg

Machine Size(LWH)

3400x1500x1750mm

Machine Size(LWH)

3400x1600x1750mm

Power Support

5 Lines 3 Phase 220/380/440V 50/60HZ

Power Support

5 Lines 3 Phase 220/380/440V 50/60HZ

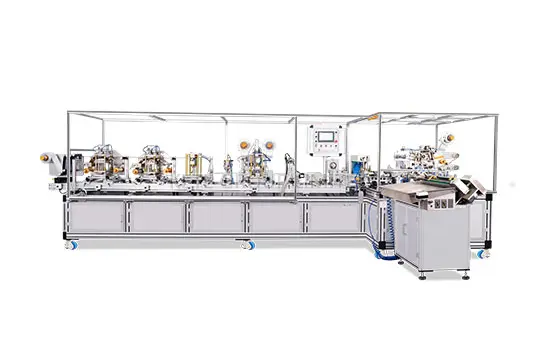

Explore Machine Workflow & Function Station

Our Machine is Designed with a Series of High-Precision Stations, Each Station Performing a Specific Function. Explore How Each Station Contributes to the Full Production Process.

From Raw Material Entry to Finished Product Delivery, Every Station is Designed to Work Seamlessly Together for Maximum Productivity and Smart Control.

Heat Shrink Sleeve Seaming Machine

Can Make PVC /PETE Sleeves

Unwind

With EPC System

Perforation

Make One Side Perforation for Easy Opening

Tear Off Tape

Make Vertical Tear Off Tape For Easy Open

Forming

Use Mold for Forming

Gluing

Use Solvent Glue for Seaming

Drying

Use Hot Air Drying Glue

Perforation

Make Two Side Perforation for Easy Opening

Rewind

Max Diameter 600mm

Layout Drawing

Our Heat Shrink Sleeve Seaming Machine Layout Size will be Different, Based on the Machine Functions of your Choice.

Download Our Latest Catalogue

Just Click Button Below to Download our PDF Catalogue

If You Want to Get More Details of KETE’s Wine Capsule Machines

and Their Data Sheet, Please Download Our Catalogue to Check,

and You Will Get Everything Clear.

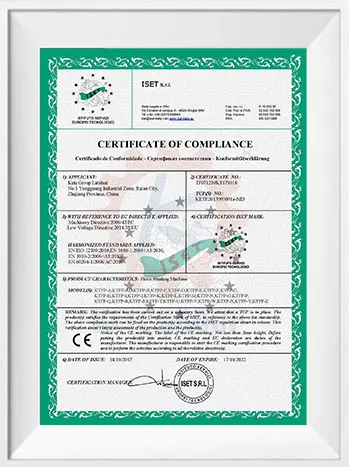

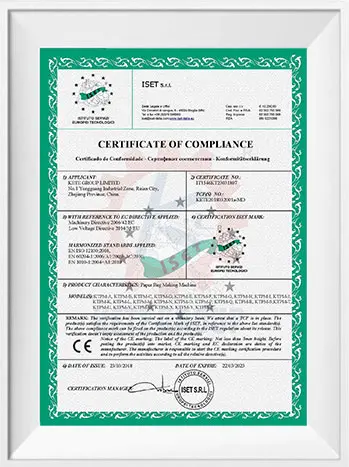

Our Certificates

We Hold CE, RoHS, ISO, and Other Key Certifications to Ensure Our Machines Meet

Global Quality and Safety Standards.

Machine FAQ

Have Questions About Our Wine Capsule Machines? Find Quick Answers to The Most Common Topics, From Machine Features and Lead Times to Installation, Maintenance, Material, And Support. If You Don’t See Your Question Here, Feel Free To Contact us directly. We’re Happy to Help.

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our KTPC-C Wine Capsule Machine Needs 40-50 Working Days, KTPC-D High Speed Wine Capsule Machine Needs 70-80 Working Days, KTPC-E Sparkling Wine Capsule Machine Needs 120-150 Working Days.

Yes, Customer Can Order Machine Only Make PVC Capsules or Only Make PET Capsules or Only Make Polylam Capsules, But Customer Also Can Order Same Machine Can Make PVC Capsules and Polylam Capsules. Even Make Aluminum Foil Capsules.

We Have KTPC-C model Wine Capsule Machine, Speed of 120Capsules/min, and KTPC-D High Speed Wine Capsules Machine, Speed of 180Capsules/min, and KTPC-E Sparkling Wine Capsules Machine, Speed of 120Capsules/min.

Yes, Our Wine Capsules Machine all Support 24-hour Working. Just Need Oiling Machine On Time.

Our Wine Capsules Machine Standard Voltage is 5 Lines, 3 Phase, 380V 50Hz. If the Customer’s Factory Voltage Was Different, We Would Add a Transformer For Free.

Our Wine Capsule Machine has CE and RoHS Certifications.

Yes, if the customer Needs, We Can Send Our Engineer to Your Factory to install the Machine and Train Your Engineer. The Customer Needs to Pay for the Engineer’s round-trip tickets, Food, Hotel, and Salary of USD150/day (8 Hours)

Our Wine Capsules Machine Warranty Period is Divided Into 1 Year and 2 Years, based on the Sales Contract Policy.

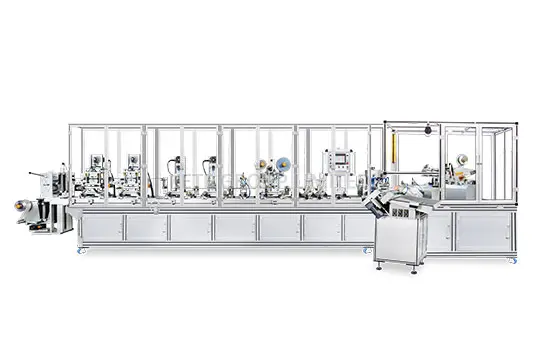

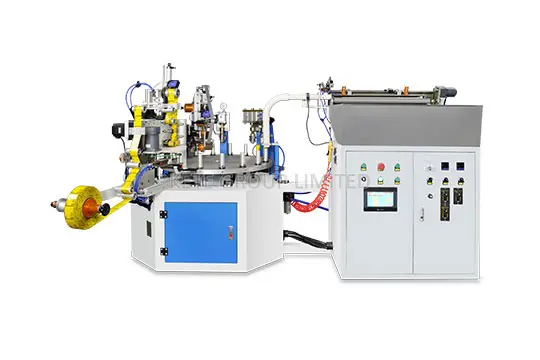

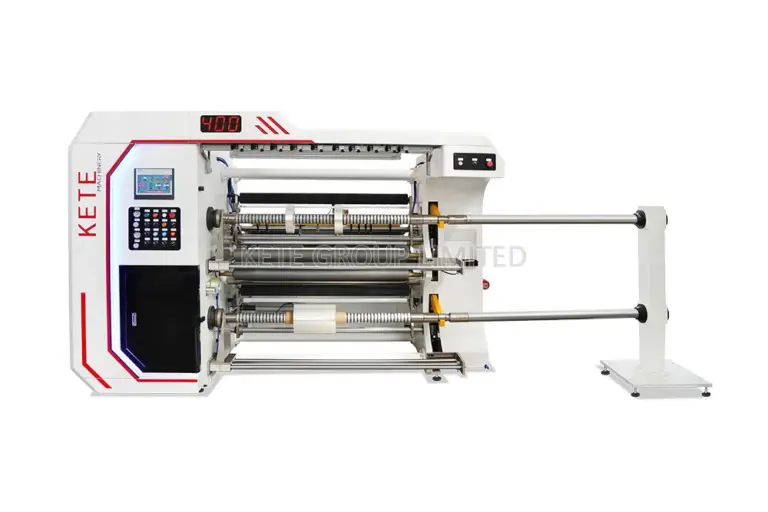

Related Machines & Equipment

We Provide Not Only Core Wine Capsule Machines but Also Matching Support Equipment, Such As Rotogravure Printing Machines,Flexo Printing Machines, Slitting Machines,

Seaming Machines, and Cutting Machines to Help You Complete Your Production Setup with Confidence.