Numerous bottled product categories make extensive use of bottle capsules with aluminum top discs. In order to maintain product integrity and a consistent brand appearance throughout packaging, shipping, and storage, this capsule structure combines sealing protection, attractive presentation, and ease of application.

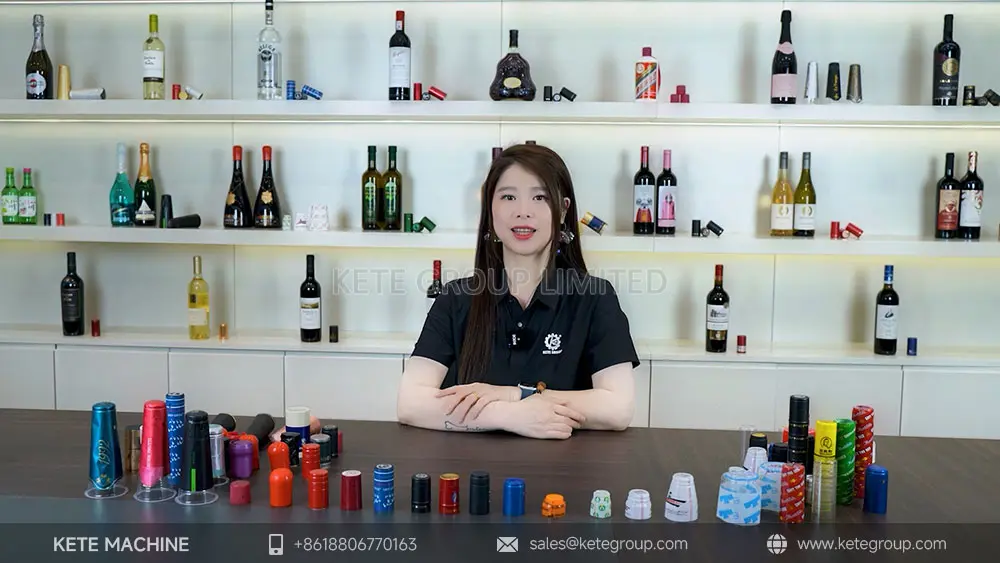

Modern bottling operations now include wine capsule design, which combines visual consistency, production compatibility, and material selection. In a variety of bottle shapes and product categories, capsules are increasingly used for equipment integration, decorative display, and functional sealing. This guide lists 7 subtypes of capsules in addition to seven main categories, arranged according to production process needs, application fit, and material type.

The standard for entry- to mid-range wines and specialty oils is still PVC capsules. The gloss level, opacity, and disc finish may be easily adjusted, and they are inexpensive and heat-responsive.

PVC capsules without a top disc – On store wines priced between €5 and €8, the cork is visible.

PVC capsules with Transparent top disc – Gives the image depth without blocking the cork.

PVC capsules with aluminum foil disc – Enhances branding contrast and tactile value.

5-gallon water tank capsules – Heat-resistant shrink films.

KEG capsules – Snap-seal finishers for beverage tanks.

LPG gas cylinder capsules – Industrial safety shrink sleeves.

Designed for heat tunnels. KETE GROUP LIMITED’s KTPC-C Series PVC Heat Shrink Capsule Making machines adjust for bottle height and shrink dwell time, eliminating shoulder wrinkles and skirt distortion.

Built from aluminum-polyethylene-aluminum layers, polylaminate offers the premium feel of tin but at reduced cost and better dent resistance-ideal for export bottlers and mid-premium SKUs.

Standard size polylam capsules – 750ml formats.

Large size polylam capsules – For magnums (1.5L+) and celebratory editions.

Available in matte, brushed metallic, glossy, and even textured finishes.

Supports spin-fit systems, KETE GROUP LIMITED’s KTPC-D Series Wine Capsule Making machines, a flexible option when running mixed SKU lines.

Designed for sparkling wines, champagne capsules combine aesthetics and function: long skirts, reinforced crowns, and precise skirt tension to align with wire hoods and CO2-driven corks.

Standard champagne capsule.

With a round tongue champagne capsule – Traditional French design.

With triangle tongue champagne capsules – Adds modern distinction for crowded shelves.

Supports spin-fit systems, KETE GROUP LIMITED’s KTPC-E Series Sparkling Wine Capsule Making machines, a flexible option when running mixed SKU lines.

The gold standard of capsule materials, tin delivers unmatched crimp precision and touch quality. Used almost exclusively for estate reds, auction lots, and cellar selections.

Cost: 2–3× higher than polylam.

Lead Time: Long, due to tooling and emboss mold production.

Handling: Tin dents easily—bulk packing is risky.

Best used with spin-head or crimp-based applicators. German company’s tooling simulation platform helps producers validate tin fits pre-run.

Screw caps are normally used on cheaper wine bottles. When paired with polylam capsules or shrink capsules, they balance functionality with branding power.

Screw Capsules – A unified capsule-closure component that ensures brand consistency and closure integrity in a single application.

Requires torque-controlled cappers. Screw systems allow shrink capsules overlays post-closure, maintaining brand aesthetics even in fast lines.

For vintners seeking handmade charm, wax capsules create vintage appeal. They work best for collector editions, limited runs, and gift-packaged bottles.

Wax Capsules – Solid molded wax units that create a distinctive seal for vintage or limited-release wines.

Incompatible with high-speed lines.

Best suited for production volumes under 2,000 bottles/month.

These are engineered for large-volume or unconventional neck designs.

Special Heat Shrink Capsules – Anti-counterfeit features with aluminum bands.

Custom tooling is a must. KETE GROUP LIMITED provides bottleneck scanning and mold-fit simulations to ensure defect-free shrinkage across irregular diameters.

For wine capsule production and application systems, KETE GROUP LIMITED offers comprehensive solutions. Please visit www.ketegroup.com or send an email to sales@ketegroup.com with any project questions or technical consultations.

We will reply you in 24hours

Introduction For many bottled products, PVC capsules without a top disk are a popular heat-shrink capsule shape. Because of its ...

Introduction For many bottled products, PVC capsules without a top disk are a popular heat-shrink capsule shape. Because of its ...

Introduction For many bottled products, PVC capsules without a top disk are a popular heat-shrink capsule shape. Because of its ...

We will reply you in 24hours

*We respect your confidentiality and all information are protected.